Drug discovery in space

Developing a new drug can take over a decade. Much of this time is consumed by trial-and-error during early R&D stages, where researchers face fundamental challenges like protein crystallization and tissue modeling.

Space offers an unexpected solution.

In microgravity, the physics of biology changes dramatically:

Protein crystals grow larger and more uniformly, making structural analysis easier and drug design more precise

Cells float freely without settling, enabling 3D tissue cultures that better mimic human physiology

Molecular interactions occur without gravity-induced interference, reducing experimental variability

“Microgravity-grown crystals are more uniform, structurally improved, and often larger,” says Prof Anne Wilson of Butler University. “They have an 80% or better chance of being superior to Earth-grown counterparts.”

This isn't theoretical speculation. Over 500 drug-related experiments have already taken place aboard the International Space Station (ISS), with companies like Merck sending blockbuster therapies like Keytruda to orbit for optimization studies.

From experiment to industry: The Varda breakthrough

February 2024 marked a turning point for biotech in space.

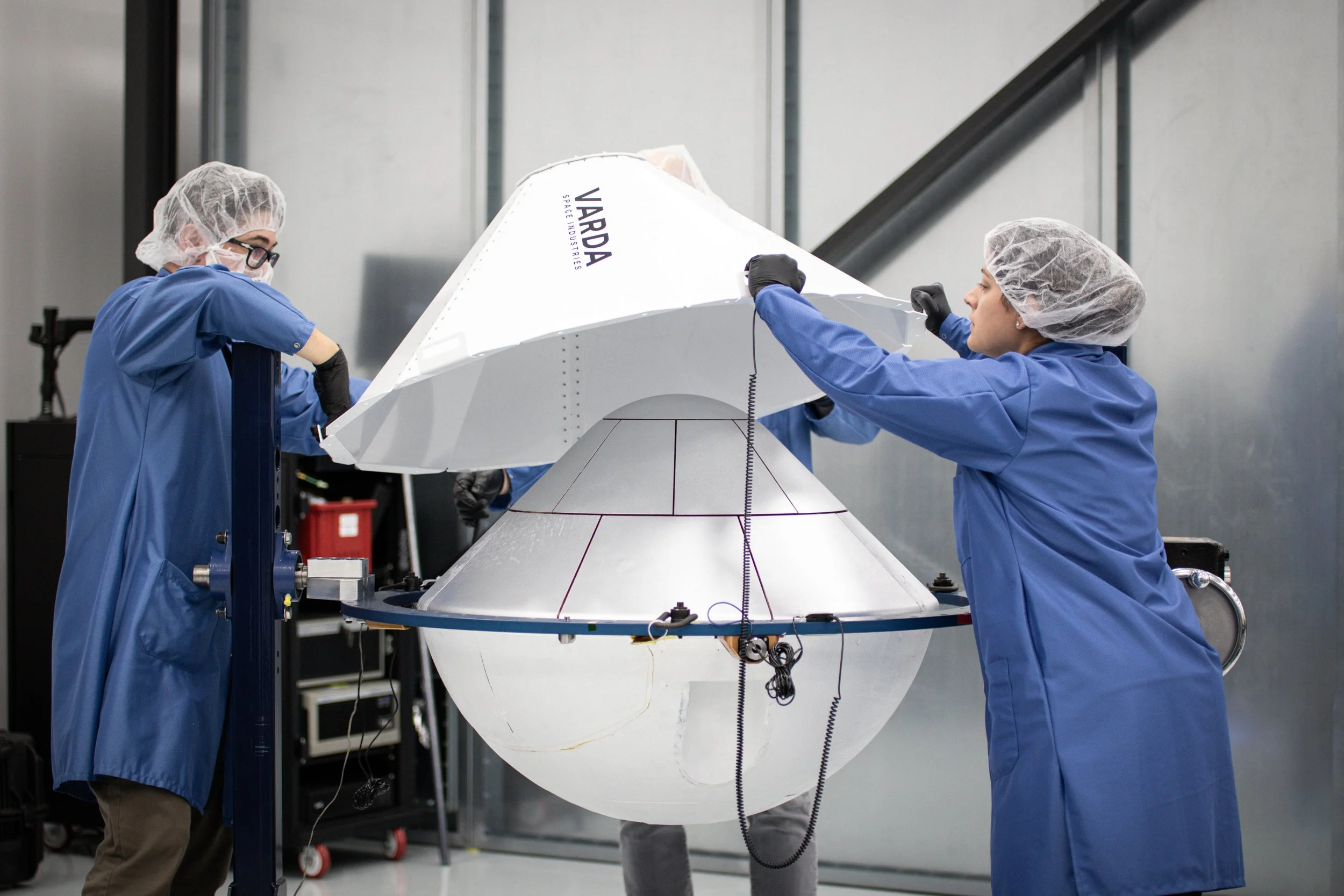

A washing machine-sized capsule from Varda Space Industries landed in Utah's desert, carrying something unprecedented: a batch of ritonavir manufactured entirely in orbit.

This wasn't just another space experiment - it was the first autonomous satellite-based drug manufacturing and return mission in history.

The mission timeline tells the story:

June 2023: Launch aboard SpaceX Falcon 9

Orbit phase: 27-hour ritonavir manufacturing test

Eight months later: Successful reentry and recovery for analysis

"Varda's re-entry system is really the most pioneering part of what they're doing," notes Dr Katie King of UK-based BioOrbit. "It opens the space for other companies to use microgravity in a variety of new applications."

This success has paved the way for Varda's second mission, which will carry their first commercial pharmaceutical payload.

Building the space biotech ecosystem

Varda's achievement represents more than a single company's success - it signals the emergence of space as commercial biotech infrastructure. The company has systematically built the capabilities needed for orbital drug production:

$329 million in funding to scale operations

10,000 sq ft laboratory in California with former pharma crystallization experts

Reusable spacecraft designed for routine manufacturing missions

Meanwhile, the broader ecosystem is rapidly expanding:

Exobiosphere is developing microgravity drug discovery platforms with European Space Agency backing

SpacePharma, Redwire, and BioOrbit are developing automated orbital laboratories and reformulation technologies. SpacePharma's collaboration with Roche Diagnostics, called SPANCER (SPAce-based bioprinted caNCER models), focuses on creating 3D-bioprinted tissues that mimic ALK-positive non-small cell lung cancer (NSCLC).

These companies treat space not as an exotic research destination, but as a new manufacturing layer for the biotech industry.

The science behind the advantage

What makes microgravity so valuable for drug development becomes clear when examining specific applications:

Protein crystallization: Earth's gravity often prevents proteins from forming the perfect crystals needed for structural analysis. In space, these same proteins can form larger, more uniform crystals that reveal crucial details for drug design.

3D cell culture: Traditional cell cultures grow flat against surfaces due to gravity. Microgravity allows true three-dimensional growth, creating tissue models that more accurately represent human biology.

Accelerated research: Space's unique stressors - radiation, oxidative damage - compress biological processes that normally take years into months, enabling faster aging and disease research.

The economics of orbital manufacturing

The commercial viability of space biotech hinges on dramatically falling costs.

Varda's first mission cost $12 million, but the company is targeting just $2 million per flight for future missions. This significant reduction comes primarily through reusable spacecraft that decrease turnaround times and marginal costs.

The economics become even more compelling when considering production capacity - each mission can potentially yield up to 100kg of drug materials. This creates a new paradigm where biotech companies can essentially rent orbital manufacturing capacity for molecules that simply cannot be produced effectively on Earth's surface.

As launch costs continue to decrease and production efficiency improves, the financial equation increasingly favors space-based manufacturing for high-value pharmaceutical compounds.

Real-world impact: From orbit to patient

This isn't just about space exploration - it's about delivering better health outcomes on Earth:

Enhanced drug efficacy: Space-grown crystals dissolve more predictably in the human body, improving absorption and reducing side effects.

New formulations: Complex injectable medications could become oral treatments using space-manufactured materials.

Disease modeling: Space's unique environment accelerates aging and stress responses, allowing researchers to test interventions for Alzheimer's, kidney disease, and immune disorders in much shorter timeframes.

The prescription from space

We're witnessing space transform from scientific playground to working pharmaceutical laboratory. With proven commercial missions, established manufacturing processes, and promising patient outcomes on the horizon, your next breakthrough medication might arrive not from a traditional lab - but from a capsule that began its journey in orbit.

The question is no longer whether space will reshape drug development, but how soon this new frontier will deliver its first life-changing therapies.

📫 Stay ahead of healthcare innovations with my weekly newsletter - get the latest medical, biotech, and digital health advances in a 5-minute briefing. Join here!